Here at the Skiers Lounge the boot fitting team have been producing thousands of footbeds (Insoles) for customers, whether it is to deal with pain or discomfort, or to improve sporting performance. For those with medical issues such as Plantar Fasciitis (Aching heels and arches) a custom made footbed can speed up recovery considerably and help prevent further issues.

The key benefits of a custom footbed are:

– By having a customised mould of your feet, the footbed stabilises the foot and in turn the ankle, knee and hip joints reducing the risk of injury

– Footbeds help reduce fatigue caused by prolonged activity with insufficient arch support allowing you to focus on your skiing or other sports

– They also help with recovery from Plantar Fasciitis, also know as Policeman’s Heel

– Custom insoles offer cushioning for impact sports such as distance running and tennis, and it is also still required in ski boots

– A custom footbed allows your boot fitter to perfectly position the foot in the ski boot, and then make adjustments to your ski boots whilst the foot remains in the correct position at all times

– Same day. No waiting for footbeds to be produced by a 3rd party, the product is moulded on the premises

The alignment and support of your feet to ensure prolonged alignment are key to ensuring good posture, reduced impact on joints, and reduced fatigue, whilst improving comfort.

We provide a variety of footbeds to customise your footwear, depending on your sport or past-time, or a particular issue you may have. We use Sidas Conform’able footbeds and the latest techniques for ensuring a perfect result.

Custom footbeds are by appointment so you get the focus of a boot fitter for the duration of your appointment, and it it only takes a couple of minutes to book online.

OUR FOOTBED VIDEO GUIDE

CUSTOM FOOTBEDS EXPLAINED

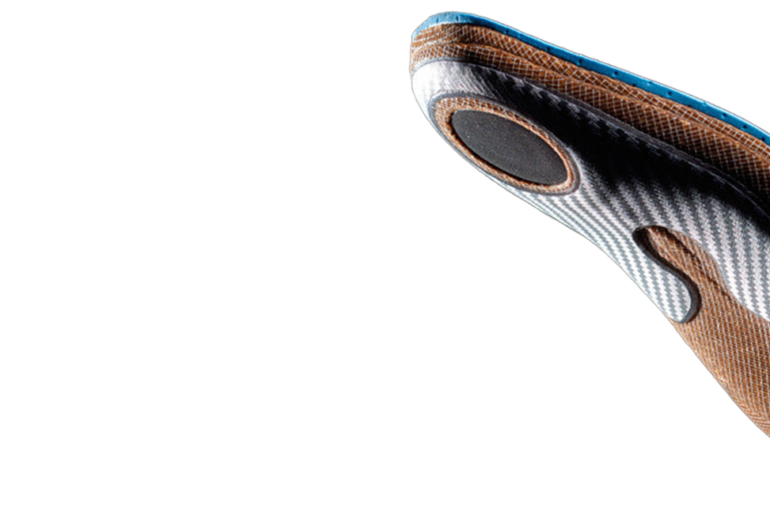

The footbed starts as a flat sheet, constructed of layers of resin, carbon, fibreglass and moulding compounds, with a dense padded top layer. We carry several types of footbeds to suit a variety of sports and situations, from dress shoes to tennis shoes!

EXAMPLE – The Custom Comfort – A multi-purpose footbed for ski and snowboard boots, walking shoes, trainers and your day-to-day shoes:

THE CUSTOM FOOTBED PROCESS – TAKES 30-60 MINUTES

STEP 1 – INTERVIEW

We make a nice cup of tea or coffee, and talk about YOU. What are you looking to achieve with your footbeds? Do you have any issues with your feet cure, or your knees, legs, lower back etc. The feet have a lot to cope with, and it doesn’t take much for problems at your feet to translate further up your body. Now we have a basic understanding about you, we move on to the next step.

STEP 2 – ANALYSIS

We have some great equipment to help us with the next steps, our eyes being the best ones! We tried fancy electronic balance systems but decided not to install this and be more hands on instead. (don’t get us wrong, they do work). We analyse your feet and also look at your biomechanics (I.e. we ask you to bend zee knees) as the amount of flexibility you have will impact how much you can flex a ski boot and your lower leg behaviour in a boot.

STEP 3 – CREATION

We now create the mould of your feet. This is done with a specialist machine with two vacuum bags with silicone gel. We align you on the machine and take an imprint of your feet in true 3D. Whilst this is happening, we are warming up a special vacuum oven, and place the selected footbeds in the oven for 3-5 minutes to activate the resin and create a mouldable footbed. We will initially ask you to stand, and then sit down as we continue to to set your custom mould.

We then place the softened footbed in the mould, and pop you back on top, where we ask you to remain still for around 5 minutes. We normally use a seated technique to produce your footbeds. Once the footbeds have cooled off, we take them for post moulding, reshaping the dimensions, and adding any additional heel support or stabilisation if necessary.

Fitter Dudley grinding the heel stabiliser on the custom insoles to get the perfect base and alignment

STEP 4 – INSTALLING YOUR CUSTOM FOOTBEDS

Finally the footbeds are slipped into your ski boots or shoes, and final checks are made. You are then all finished. You will find the sensation a little different for a couple of minutes as in particular your arches will not be used to having support, but that will soon disappear as the feet realise they have a new ally to help keep you aligned, in balance, and comfortable!

The finished custom insole on the left and the original flat foam insole on the right

Book a custom insole appointment

You can make an appointment for custom insoles to be added to your existing ski boots or footwear, with our 24/7 online booking system. Prices range from £90 to £140 for a custom footbed. Our best selling ski footbed complete with fitted heel stabiliser is £120, or £99 with a ski boot fitting bought from us, and comes with our comfort guarantee.