We are one of the first ski boot fitters to take on board the Solemate 3D Footbed System, offering scanning fittings for custom ski boot insoles manufactured with the latest in 3D printing technology and materials. We have been using 3D printing on-site for a year now to produce parts for ski boot fittings, and there are all ready a few hundred of these items carving across the mountains. So for us, 3D printed insoles offer some genuine benefits and an alternative to the moulded footbeds we produce currently for most of our customers.

Why Do I Need 3D Printed Custom Footbeds?

The question really should be, why do I need custom footbeds, and I cover that off in this hopefully useful video about custom footbeds.

What is different about a 3D Printed Custom Footbed vs A Custom Moulded Footbed?

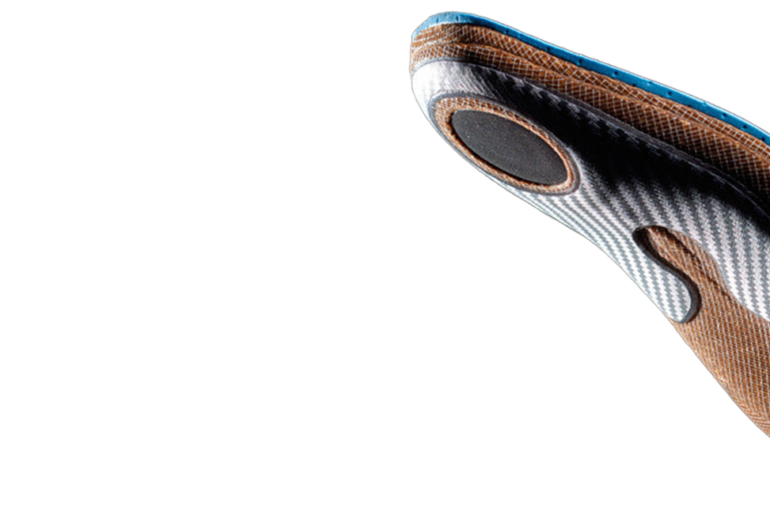

Where 3D printed footbeds vary slightly is in that they offer us the opportunity to give an even more precise mould of your foot using 3D scanning technology developed by Solemate. We not only carry out the full assessment as we do with any custom made footbed, but we then produce 3D scans of your feet, rather than using our moulding system, allowing us to get even more accurate results. Further, we can undertake bespoke work with the 3D custom printed footbed that we cannot do with our popular moulded footbed offering:

- Fine tune the thickness of the footbed to help reduce or increase space over the instep and top of the toes as required

- Adjust the stiffness of the footbed before production to give you a comfort, standard or performance level of support

- Incorporate a heel lift directly into the footbed, so that we do not have to add one inside the boot sticking it in place. This reduces the risk of the heel lift moving

- Allow us to make very precise adjustements such as “posting” to mitigate existing issues with your foot biomechanics for the most comfortable result possible

- Incorporate elements from boot heating systems, so that your boot heating system is as efficient as possible and the cables are sat in channels to prolong the life of your elements and not interfere with the fitting

- Allow us to print further “copies” of your 3D printed footbeds for ski boots, and also other day shoes or sports footwear

Are there any difference in the way my fitting works and when I get my footbeds?

Yes! The actual scan is much quicker than standard moulding process we offer. Where properly moulding a footbeds ready to reshape and grind it takes around 10-15 minutes, for a 3D scan for your 3D Printed footbed its around 3-5 minutes. Here is a video by Tom, the chief designer at Solemate showing a typical process.

For a custom moulded footbed, we will then spend a further 15-20 minutes applying a heel stabiliser and any adjustments, grinding the footbed, and then cutting the shape to fit your ski boots.

With a 3D Printed footbed, once we have scanned the foot and quality control checked it, the scan is sent off for production at a dedicated printing facility (known as a print farm!) with the production monitored and the result quality control checked before either shipping back to us for you to come in and check for final fitting OR the footbed can be posted to you directly to insert into the ski boots. The process of printing and posting the 3D printed footbeds to us or yourself to insert them takes around 7 working days.

So should I buy a custom moulded footbed OR a 3D printed footbed with my ski boots?

We would say if you are happy with coming back for a quick follow up session to install your 3D Printed footbed, or happy to insert them yourself, the benefits of increased precision, even more customisation, enhanced comfort plus reduced waste, a 3D Printed footbed by Solemate is very much worth considering for the ultimate fit. IF you want to leave the end of your ski boot fitting with us with everything ready to go and hit the mountain, then a moulded footbed will offer the opportunity to do this.

PRICING

The price below includes your appointment for a scan, a quality control review, production of the footbed which takes 12 hours on the latest 3D printing machines with a specialist material which is long lasting, and shipping to yourself directly or us to arrange to install the footbed and perform final checks for you. We do recommend popping back to us for your final checks, as when doing this we will wait until you come in to heat the liners up to undertake the final boot moulding too. If you wish the footbeds to be sent direct as you cannot visit again, we will heat mould your boots with the test Solemate footbed, and then you can install the footbed when they arrive with you…

- Consultation, 3D Scan and production of a full set of footbeds – £150.00

- As above with Therm-IC or Carv I Inset and cable ports – £180.00

- Second set from identical scan (stiffness may be adjusted) – £120.00

MAKE A BOOKING

Our booking system is live and real time, so you can take a look at our availability and make a booking. We do NOT charge for boot fitting. The cost of a 3D printed footbed is £150-£180 including assessment and materials…